A CNC router is specifically used for woodworking projects to automate and enhance the precision, complexity, and efficiency of cutting, carving, and shaping wood. It accomplishes a wide range of tasks that traditionally required manual labor and skill, but with greater speed and accuracy. Here are the main ways CNC routers are used in woodworking:

- Cutting and shaping: CNC routers cut wood panels and blocks into precise shapes for furniture parts, cabinetry, doors, and other components. The router moves along programmed paths to create exact dimensions and cuts multiple shapes from a single piece of wood with minimal waste.

- Carving and engraving: These machines can carve intricate 2D and 3D decorative patterns, text, logos, and relief designs on surfaces. This is ideal for custom woodcrafts, sign-making, moldings, and artistic furniture features that require detailed craftsmanship.

- Hollowing and routing: CNC routers hollow out specific areas for joinery or design purposes, such as creating recesses for hinges, inlays, or grooves. This makes complex joinery such as dovetail or mortise-and-tenon joints consistently precise and reproducible.

- Prototyping and custom projects: Woodworkers use CNC routers to quickly produce prototypes or unique custom pieces. This allows fast iteration with minimal material waste, enabling more creativity and innovation.

- Furniture manufacturing: CNC routers are widely used in production environments where consistency and scalability matter—from chairs and tables to cabinet doors and panels. They cut and shape parts with repeatable precision for assembly lines.

- Sanding and finishing: Some CNC routers are equipped with sanding attachments that automate surface finishing, ensuring smoothness and readiness for painting or varnishing.

- Efficiency and safety: CNC routers reduce manual handling of large panels, minimize operator fatigue, and enhance workplace safety by automating dangerous cutting operations.

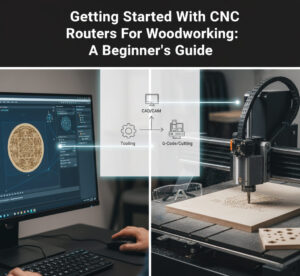

In operation, woodworkers create digital designs using CAD software, which are converted via CAM software into machine-readable toolpaths. The CNC router then executes these programmed instructions to cut and carve the wood precisely as designed.

In summary, CNC routers allow woodworking professionals and hobbyists to achieve complex, highly detailed, and consistent results with less time and effort compared to traditional manual woodworking methods, opening new creative and production possibilities.